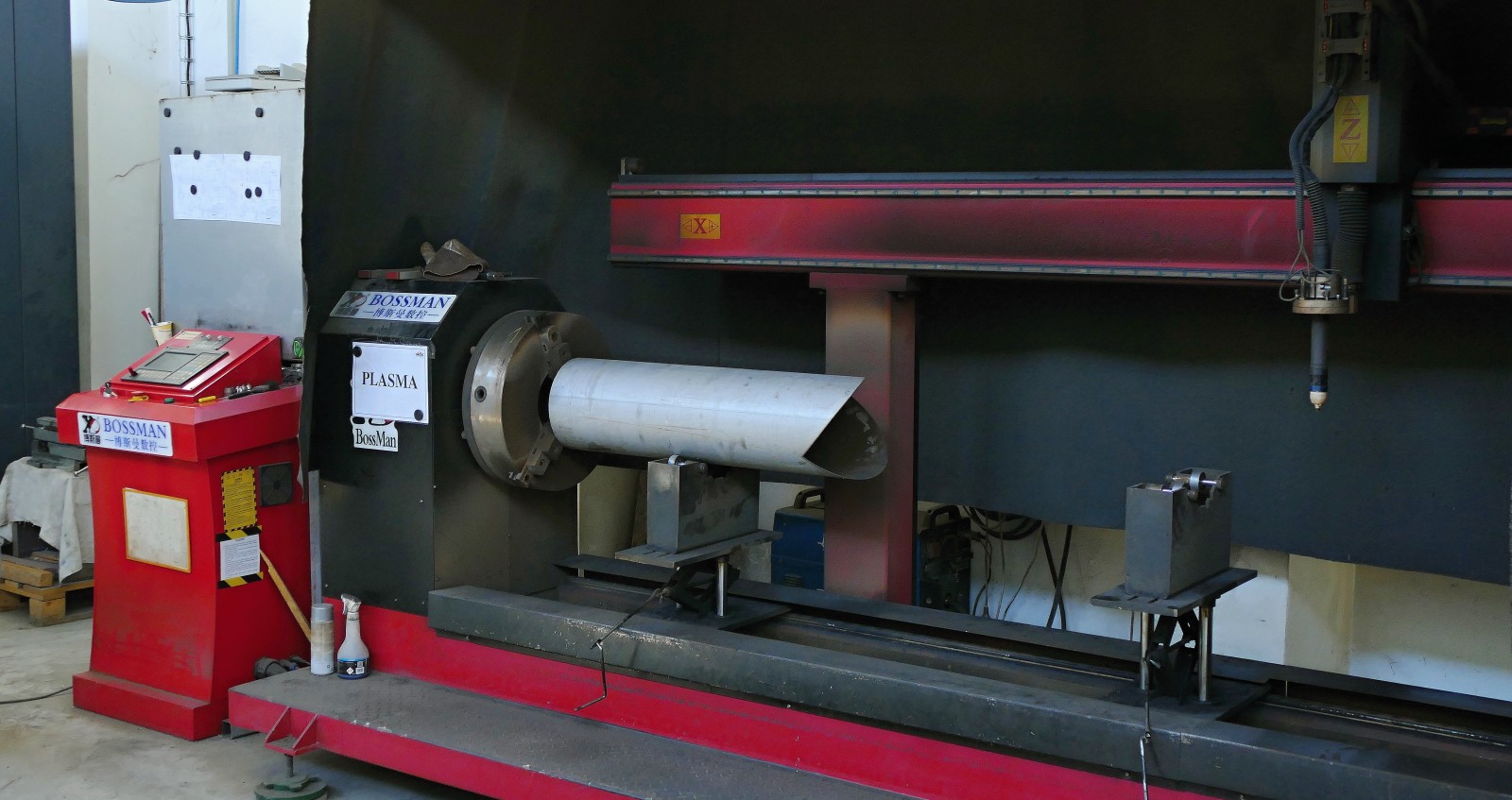

Assembly units and the parts of machines for industry.

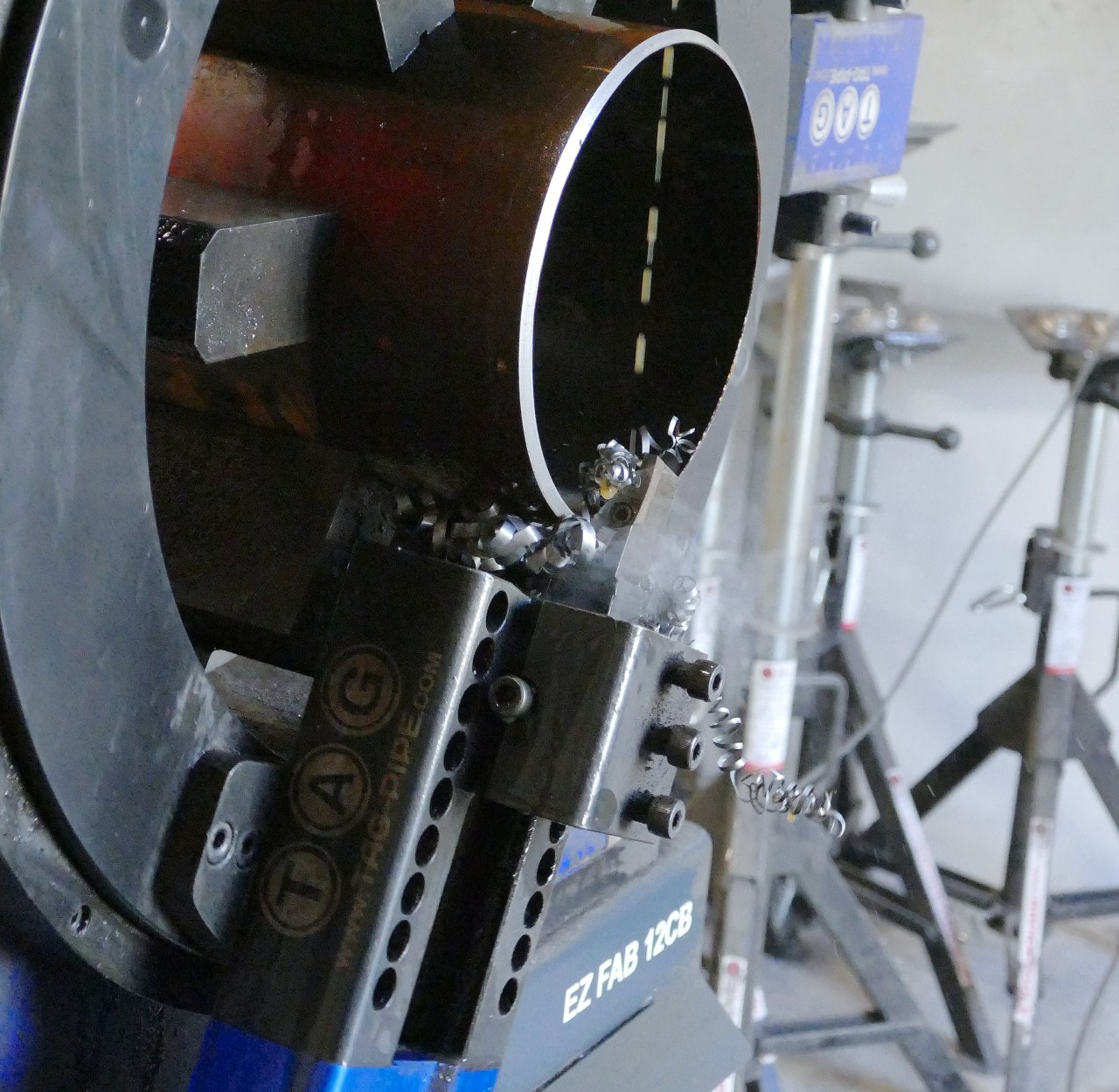

Pressure piping systems for plastic processing companies.

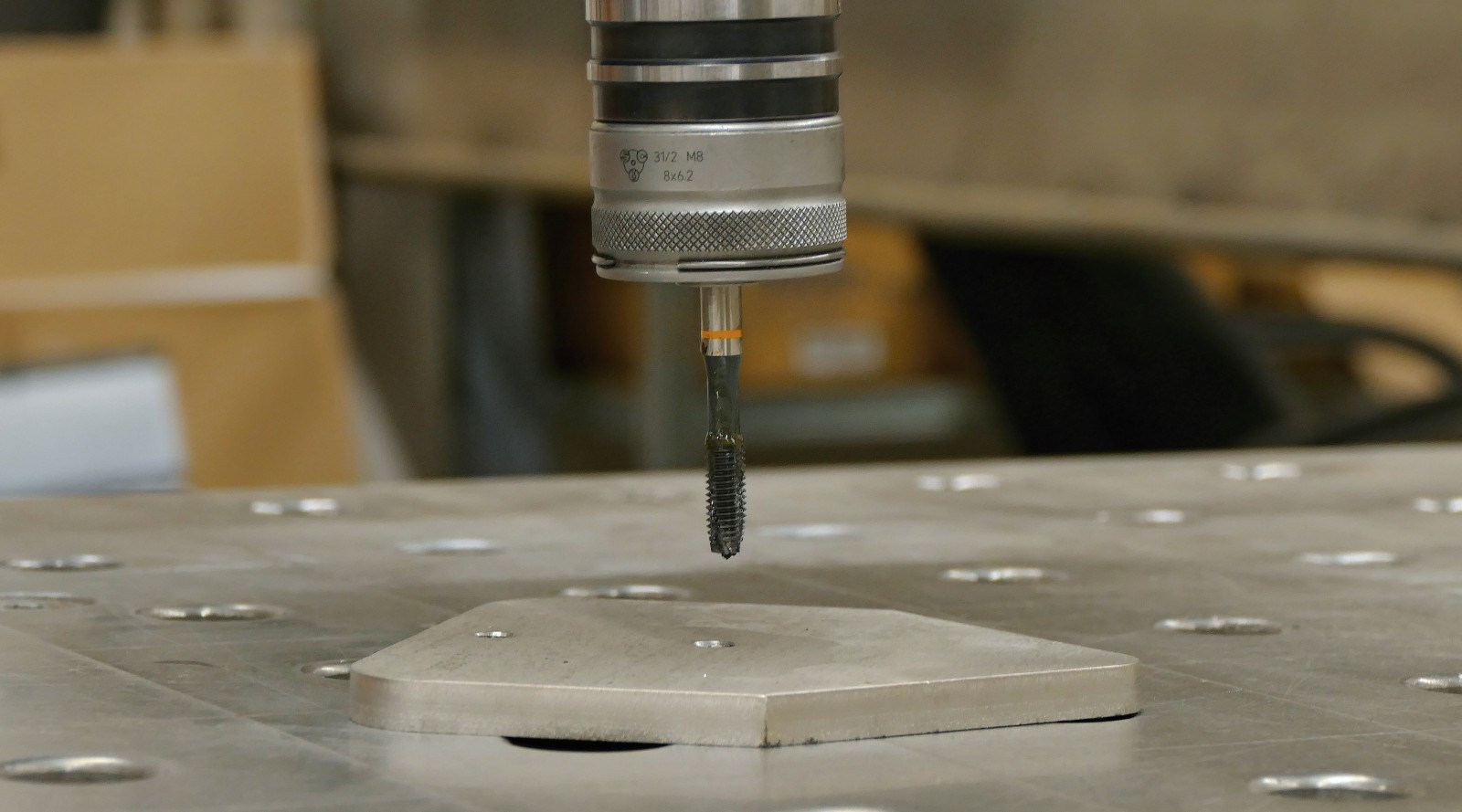

Cover plates for production lines and waterproof tanks for plastic recycling.

In recent years, we have built constant customers for whom we produce components or larger parts.

Pressure piping systems for plastics processing companies

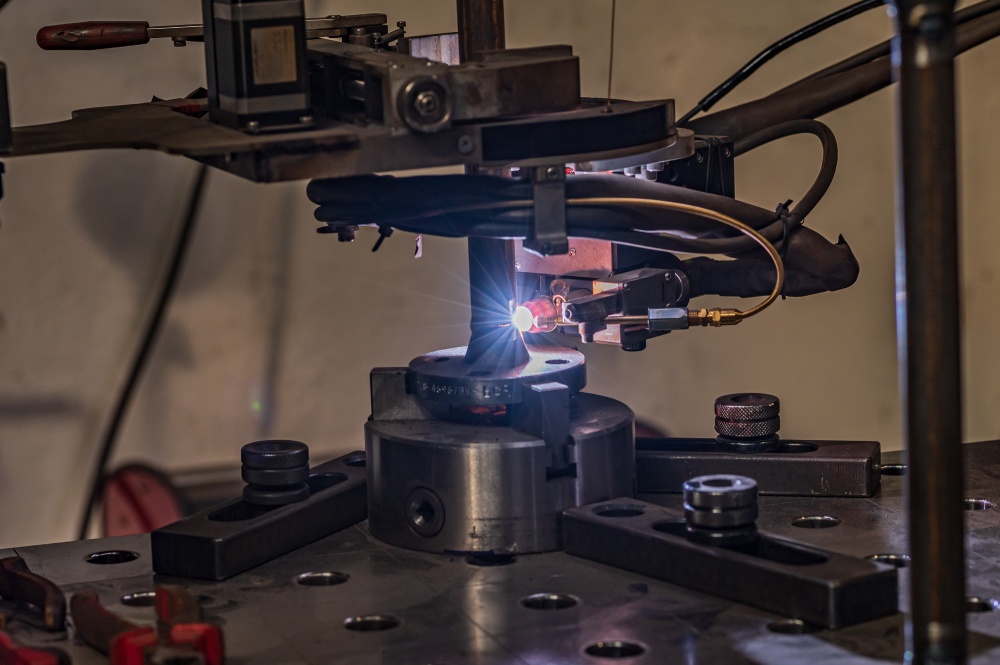

Supporting welded frame for assembly of machine components

Cover plates for production line components

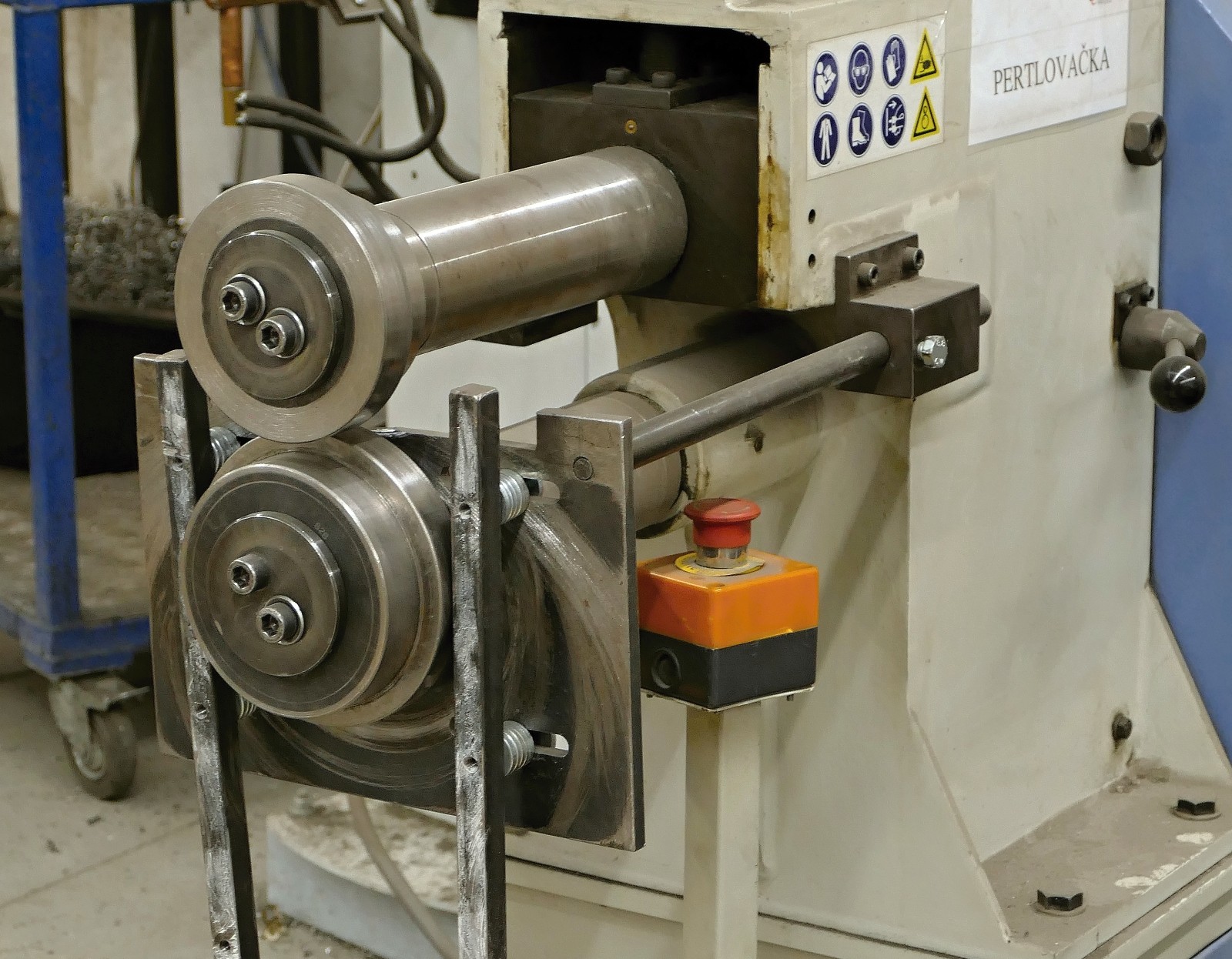

Various rotating and spatial components

Assembly of machines parts and components

Plastic recycling tanks

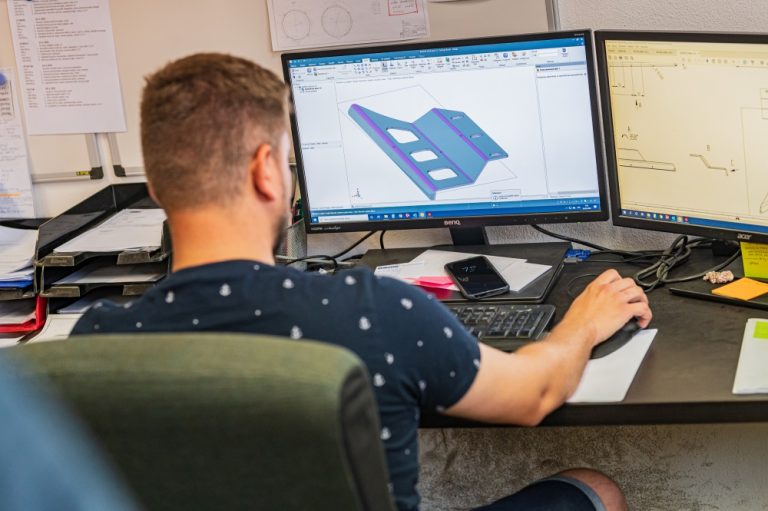

We have experience on the field of engineering for several years. We work with modern technologies that can guarantee high quality and other customer requirements.